SPR-3530P Concrete Color Sealing Curing Agent Floor System

Project Features:

1、Hard:After being treated with permeable sealing and hardening materials, the Mohs hardness of the ground will reach 8 to 9, and the Mohs hardness will be increased by about 45%.

2、Wear Resistance:Permeable sealing and hardening materials can solidify various components in concrete into a hard entity to increase hardness and compactness. After the ground is hardened, the wear resistance will increase to more than 8 times.

3、Dust Prevention: The permeable sealing hardening material reacts chemically with the silicate in the concrete to form a dust-free and dense whole on the concrete surface, permanently controlling the precipitation of concrete dust from the surface voids.

4、Anti Slip:On general concrete floors, salt and alkali components can precipitate from the surface, causing slippage. However, the ground with permeable sealing and hardening materials is different. It forms a solid and dense whole on the concrete surface, and salt and alkali components do not precipitate from the surface.

5、Compressive Strength:The compressive strength of the treated sample is 25% higher than that of the untreated sample, and the flexural strength is also improved.

6、Impermeability: Permeable sealing hardening materials can effectively penetrate into the concrete and react chemically with them, locking the pores inside, providing a permanent sealing effect on the concrete surface, and effectively preventing water, oil, and other surface contaminants from entering the concrete.

7、Weathering Resistance:Water spray has no adverse effect on the treated sample and can effectively prevent the passage of chloride ions. Tests have shown that the treated ground effect will not be affected by exposure to electromagnetic or water mist.

8、Corrosion Resistance:The ground treated with permeable sealing and hardening materials will greatly improve the corrosion resistance of concrete.

9、Brightness:The concrete floor treated with permeable sealing and hardening materials will have a marble like luster, and the longer it is used, the better the glossiness.

10、Environmental Protection:Permeable sealing hardening material is a concrete sealing, dustproof, wear-resistant hardening agent that is colorless, odorless, non-toxic, and nonflammable, and can make concrete strong and dustproof.

11、Variety Of Colors::Beautiful and highly decorative, commonly used colors include: green, red, black, yellow, gray, and blue.

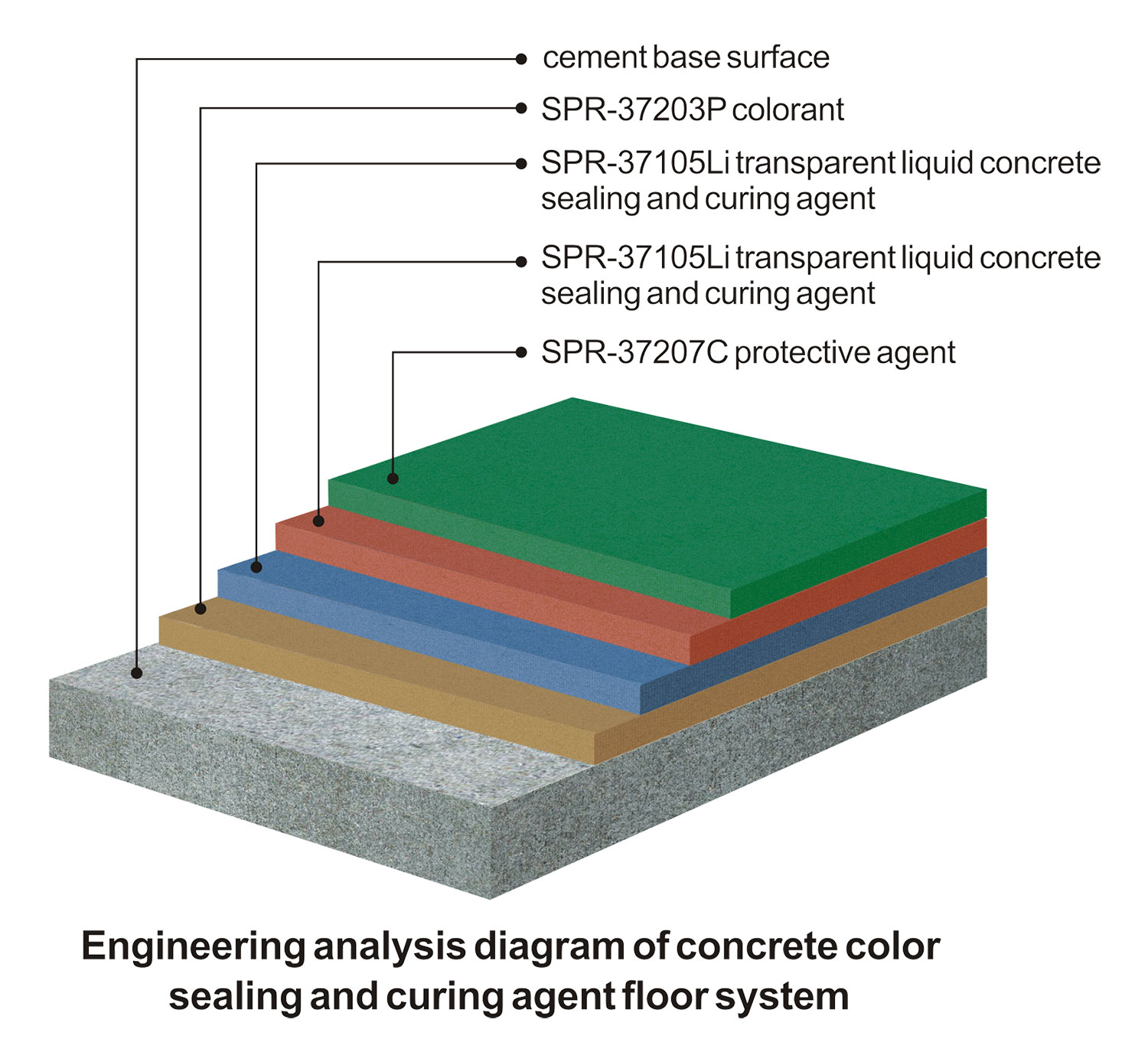

Construction Process:

Base Surface Treatment:

First, thoroughly polish the ground with a 50-500 mesh abrasive disc until it feels smooth, and thoroughly clean the ground dust with a vacuum cleaner or other tools to enable the ground pores to fully absorb material;

Spraying Material:

After the surface is dried, spray two layers of SPR-37203P dye. After the first layer of dye is applied and the surface is dried for 6-8 hours, apply a second layer of dye with a dosage of about 0.2kg/m2 (terrazzo or emery ground);

Spraying Materials:

use a spray to moisten SPR-37105Li crystal transparent liquid concrete sealing curing agent to the surface, let it naturally penetrate for 30~60 minutes, and cure the ground (3-6h);

Spraying Materials:

SPR-37105Li crystal transparent liquid concrete sealing curing agent is evenly coated on the dried ground with a spray to allow natural penetration;

Fine polishing:

After applying SPR-37105Li crystal transparent liquid concrete sealing and curing agent for 6-8 hours, use a polishing machine to install 500 mesh, 800 mesh, 1000 mesh, 1500 mesh, 2000 mesh, and 3000 mesh grinding discs for dry polishing (the polishing process ensures dry grinding, and do not carry water for operation), fine polishing and polishing three to four times until the customer's requirements are met, and use a vacuum cleaner to clean the surface;

Spraying Protective Agent:

Spray SPR-37207C protective agent (dosage: about 0.05 kg/m2) after the ground is clean and dry. After its natural surface is dry (about 6-8 hours), polish it with a 2000-3000 mesh resin abrasive plate (the polishing process ensures dry grinding, and do not carry water for operation) before use.

Place Of Application:

1.Areas that require a clean environment and have certain requirements for dust content in the air, but are not suitable for use as surface coating materials.

2. Any cement based construction material surface such as new and old concrete base, terrazzo, cement based wear-resistant ground, and cement mortar surface that requires hardness, high wear resistance, and high impermeability both indoors and outdoors, such as factories, shopping centers, warehouses, parking lots, service stations, aircraft hangars, freight distribution centers, and other areas.

-

1. What products do you manufacture?Our main products include waterborne polyurethane mortar, epoxy floor paint, liquid sealing curing agent, and weather-resistant polyurethane coatings.

-

2. What industries are your products used in?Widely used in indoor and outdoor flooring: industrial plants and commercial venues, high-speed railway stations, food factories, pharmaceutical factories, parking lots, logistics warehouses, electronic factories, textile mills, office areas, park greenways, and pedestrian walkways.

-

3. Do you provide customization or OEM/ODM services?We are a coating manufacturer, providing professional OEM/ODM services.

-

4. Can I customize the packaging?Yes, neutral or custom logo packaging is available upon request.

-

5. Are your products certified?Yes, we can provide ISO, SDS, RoHS, and other certifications upon request.

-

6. Can you provide brochures?We can provide brochures and product samples.

-

7. How can I obtain a quotation?Please send the application scene/floor coating name/project area/purchase quantity and other information to our email and leave your email address. We will provide a quotation as soon as possible and send it to your email.

-

8. Can you do EXW/FOB/CIF/DDP terms?Yes, we accept multiple trade terms, with the ports of shipment being Nansha Port and Shenzhen Port.

-

9. What markets do you serve?Our clients are spread across the United States, Australia, Africa, Southeast Asia, and other regions.

-

10. Can I get a sample first? How long will it take?Yes, samples are available. It usually takes 3–7 days depending on the complexity.

-

11. What’s the lead time for bulk orders?Bulk orders usually take 15–30 days, but may vary during peak season or for special materials, depending on the order.

-

12. Do you have stock? Is the delivery on time?Some regular models are in stock. We strictly adhere to lead times.

-

13. Can I mix different models in one order?Yes, we support mixed batch shipments to meet the functional zoning requirements of floor paint in different regions.

-

14. What are your shipping methods?We ship by air, sea, or express. FOB and CIF terms are available.

-

15. Do you accept long-term partnerships or distribution agreements?Yes, we welcome long-term partnerships and offer special pricing and support.

-

16. Where is your factory located? Can we visit?Our factory is located in Nanxiong, Guangdong, China. Appointments for visits are welcome.

-

17. What payment methods do you accept?We accept T/T, L/C, global pay, etc.

-

18. Can you issue an invoice?Yes, we provide proforma and commercial invoices for customs and payment purposes.

-

19. Can you sign a Non-Disclosure Agreement (NDA)?Yes, we respect your IP and can sign an NDA before collaboration.

-

20. Do you provide a product manual or video?Yes, PDF manuals and operation videos are available for each product.

-

21. Can you provide product training?Yes, remote training is available to help clients quickly understand the product.

-

22. Do you provide after-sales service?Yes, we provide warranty support. If there's a quality issue, we offer returns or replacements.