SPR-5311P Cement Based Non vibration Anti slip Ramp System

Project features:

1. The vibration free slip stop ramp material is composed of a variety of highly rigid mineral aggregates, Portland cement, and additives, and is constructed using a special on-site process.

2. It has a variety of excellent properties such as anti-slip, wear-resistant, comfortable and vibration free, and has beautiful and distinctive patterns and strong logo.

3. Reduce vehicle driving noise, improve driving conditions, reduce or even eliminate water splash and mist, and increase driving safety in rainy days.

4. Good low-temperature resistance, thermal aging resistance, all-weather use, and resistance to sunlight and ultraviolet radiation.

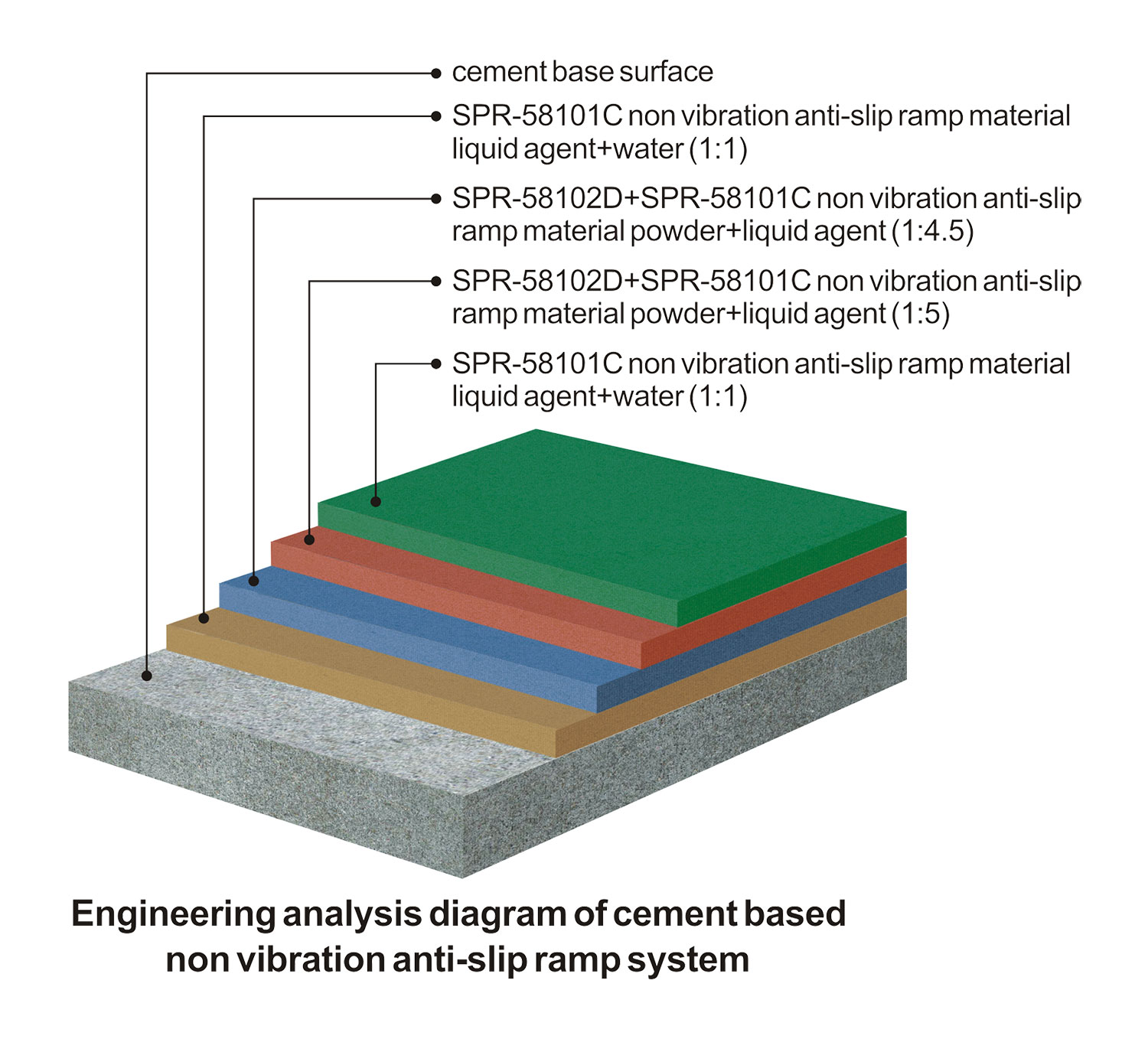

Construction process:

Ground cleaning:

Clean and polish the concrete base surface to ensure that it is free of oil, sludge, cement chips, and other attachments, and level uneven areas without hollowing and clean with water;

Interface layer:

SPR-58101C shock free anti slip ramp material liquid agent (1:1 mixing with water) is used, and roller or spray is used to evenly coat the base layer to form an interface layer;

Construction of bottom layer:

First, use SPR-58101C vibration free anti slip ramp material liquid agent: SPR-58102D vibration free anti slip ramp material powder in a ratio of 1:4.5, mix evenly, and apply it to the interface layer (generally, the bottom layer is yellow);

Paste the dividing line:

Draw a line according to the design requirements, and paste adhesive tape. The commonly used colors are yellow bottom layer and green surface layer, with a yellow bottom width of 12 centimeters, a green surface width of 30 centimeters, and an obtuse angle of about 150 °;

Surface layer construction:

first use SPR-58101C non vibration anti slip ramp material liquid agent: SPR-58102D non vibration anti slip ramp material powder in a ratio of 1:5, mix evenly, and then apply it to the bottom layer (generally, the surface layer is green);

Clean up the site:

clean up excess materials to make the ground clean and free of pollution;

Curing layer:

Use SPR-58101C vibration free anti-slip ramp material liquid agent (1:1 mixed with water) to evenly coat the surface of the product with a roller to maintain the finished product.

Scope of application:

Applicable to road intersections, bicycle roads, bus lanes, car ramps, pedestrian passages in residential areas, slopes, roads, and other parts with special slip resistance requirements, and beautification areas.

-

1. What products do you manufacture?Our main products include waterborne polyurethane mortar, epoxy floor paint, liquid sealing curing agent, and weather-resistant polyurethane coatings.

-

2. What industries are your products used in?Widely used in indoor and outdoor flooring: industrial plants and commercial venues, high-speed railway stations, food factories, pharmaceutical factories, parking lots, logistics warehouses, electronic factories, textile mills, office areas, park greenways, and pedestrian walkways.

-

3. Do you provide customization or OEM/ODM services?We are a coating manufacturer, providing professional OEM/ODM services.

-

4. Can I customize the packaging?Yes, neutral or custom logo packaging is available upon request.

-

5. Are your products certified?Yes, we can provide ISO, SDS, RoHS, and other certifications upon request.

-

6. Can you provide brochures?We can provide brochures and product samples.

-

7. How can I obtain a quotation?Please send the application scene/floor coating name/project area/purchase quantity and other information to our email and leave your email address. We will provide a quotation as soon as possible and send it to your email.

-

8. Can you do EXW/FOB/CIF/DDP terms?Yes, we accept multiple trade terms, with the ports of shipment being Nansha Port and Shenzhen Port.

-

9. What markets do you serve?Our clients are spread across the United States, Australia, Africa, Southeast Asia, and other regions.

-

10. Can I get a sample first? How long will it take?Yes, samples are available. It usually takes 3–7 days depending on the complexity.

-

11. What’s the lead time for bulk orders?Bulk orders usually take 15–30 days, but may vary during peak season or for special materials, depending on the order.

-

12. Do you have stock? Is the delivery on time?Some regular models are in stock. We strictly adhere to lead times.

-

13. Can I mix different models in one order?Yes, we support mixed batch shipments to meet the functional zoning requirements of floor paint in different regions.

-

14. What are your shipping methods?We ship by air, sea, or express. FOB and CIF terms are available.

-

15. Do you accept long-term partnerships or distribution agreements?Yes, we welcome long-term partnerships and offer special pricing and support.

-

16. Where is your factory located? Can we visit?Our factory is located in Nanxiong, Guangdong, China. Appointments for visits are welcome.

-

17. What payment methods do you accept?We accept T/T, L/C, global pay, etc.

-

18. Can you issue an invoice?Yes, we provide proforma and commercial invoices for customs and payment purposes.

-

19. Can you sign a Non-Disclosure Agreement (NDA)?Yes, we respect your IP and can sign an NDA before collaboration.

-

20. Do you provide a product manual or video?Yes, PDF manuals and operation videos are available for each product.

-

21. Can you provide product training?Yes, remote training is available to help clients quickly understand the product.

-

22. Do you provide after-sales service?Yes, we provide warranty support. If there's a quality issue, we offer returns or replacements.