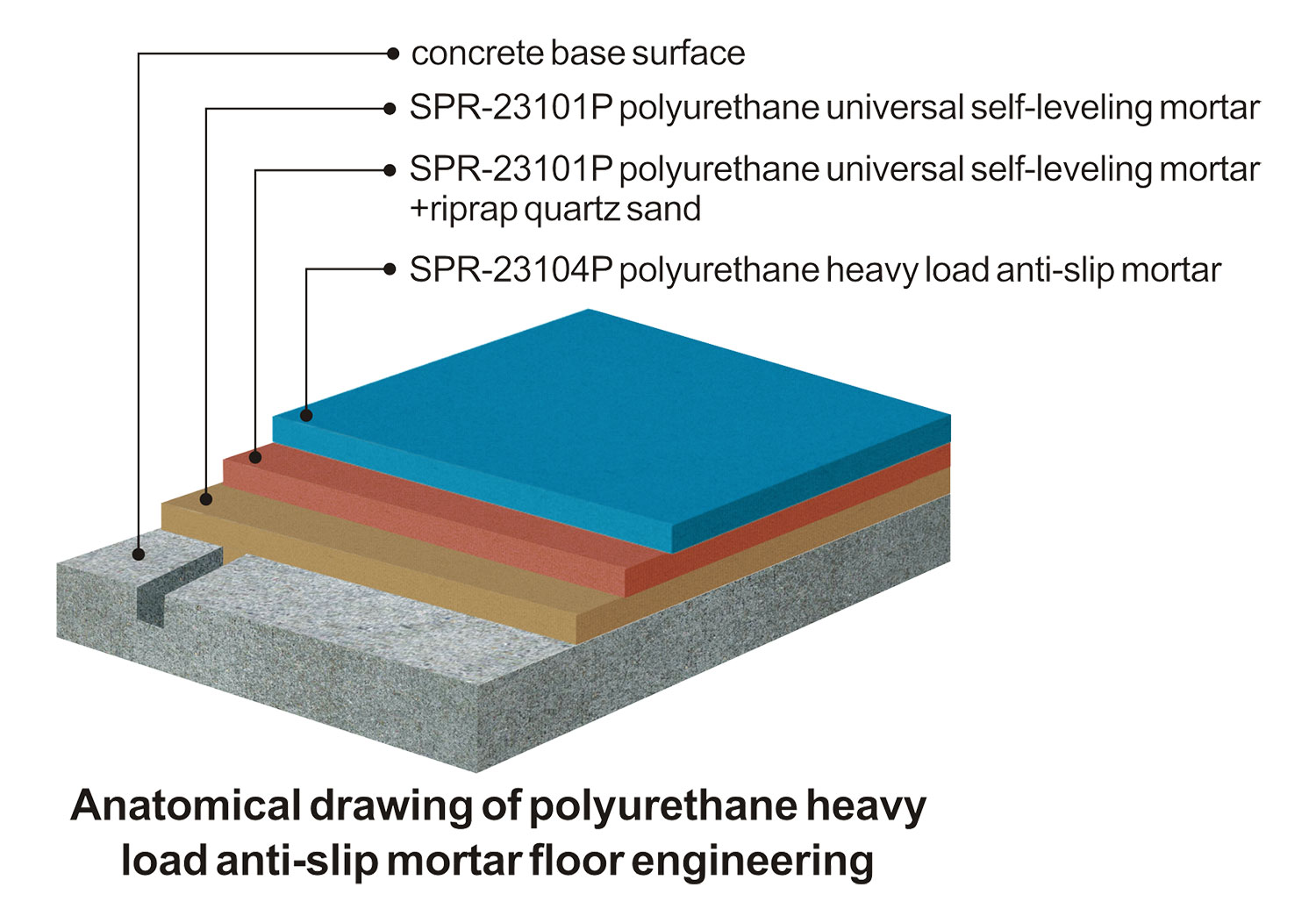

SPR-2311P Polyurethane Heavy Load Anti slip Mortar Floor System (HD)

Project features:

Polyurethane heavy-duty anti-slip mortar is a four component color water-based self-leveling mortar floor coating made of high-performance polyurethane resin as the base material, and special cement, graded silica sand, and active pigments as the aggregate; Excellent impact resistance, damage resistance, chemical resistance, and scrub resistance; Capable of withstanding heavy loads and a high degree of slip resistance.

Construction process:

Base surface treatment

The treatment of base concrete is the key to making a good polyurethane concrete floor. The quality of ground treatment directly affects the service life of the floor. In order to enhance the adhesion between the base and the floor, mechanical treatment is required to expose concrete aggregates (such as shot blasting). The floor surface must be grooved, with the depth and width of the groove being 2-3 times the thickness of the polyurethane mortar floor; In particular, all edges (such as trenches, etc.) should be grooved at a distance of 20mm.

Primer application

After the base surface is cleaned, mix the SPR-23101P polyurethane universal self-leveling mortar material evenly according to the design ratio, pour another bucket for mixing again, and then use the scraping and coating method for batch scraping construction. Strictly control the filling of each groove and gap. After mixing the material, use a trowel to continuously pave it. This step cannot be interrupted, and needs to be completed as soon as possible to ensure better adhesion of the material. To ensure that the base layer is completely sealed, a polyurethane primer of 1 mm is suitable. Grinding after solidification of the primer: After solidification of the polyurethane mortar primer, it is necessary to grind the rough primer with a grinder to increase the adhesion between subsequent coatings.

Grinding after solidification of the primer

After solidification of the polyurethane mortar primer, it is necessary to grind the rough primer with a grinder to increase the adhesion between subsequent coatings.

Sanding construction for the middle layer

Mix the SPR-23101P polyurethane universal self-leveling mortar material evenly according to the design ratio, pour another bucket for mixing again, use a nail rake to evenly spread the material according to a certain thickness, and then sprinkle quartz sand.

Surface layer construction

Evenly mix the SPR-23104P polyurethane heavy-duty anti-slip mortar according to the proportion (using a low-speed double-head or spiral blade mixer), pour another bucket and mix again. After that, evenly spread the material with a trowel according to a certain thickness, pave it with a trowel, and continuously pave the material after mixing. This step cannot be interrupted, and needs to be completed as soon as possible to ensure better surface effect and adhesion.

Scope of application:

low-temperature freezer, high-temperature decontamination area, boiling water and scalding operation room; Areas such as frying rooms, slaughterhouses, and treatment areas that have oil, water, high temperatures, and require a high degree of slip resistance; Areas requiring high temperature hot water vapor pressure flushing.

-

1. What products do you manufacture?Our main products include waterborne polyurethane mortar, epoxy floor paint, liquid sealing curing agent, and weather-resistant polyurethane coatings.

-

2. What industries are your products used in?Widely used in indoor and outdoor flooring: industrial plants and commercial venues, high-speed railway stations, food factories, pharmaceutical factories, parking lots, logistics warehouses, electronic factories, textile mills, office areas, park greenways, and pedestrian walkways.

-

3. Do you provide customization or OEM/ODM services?We are a coating manufacturer, providing professional OEM/ODM services.

-

4. Can I customize the packaging?Yes, neutral or custom logo packaging is available upon request.

-

5. Are your products certified?Yes, we can provide ISO, SDS, RoHS, and other certifications upon request.

-

6. Can you provide brochures?We can provide brochures and product samples.

-

7. How can I obtain a quotation?Please send the application scene/floor coating name/project area/purchase quantity and other information to our email and leave your email address. We will provide a quotation as soon as possible and send it to your email.

-

8. Can you do EXW/FOB/CIF/DDP terms?Yes, we accept multiple trade terms, with the ports of shipment being Nansha Port and Shenzhen Port.

-

9. What markets do you serve?Our clients are spread across the United States, Australia, Africa, Southeast Asia, and other regions.

-

10. Can I get a sample first? How long will it take?Yes, samples are available. It usually takes 3–7 days depending on the complexity.

-

11. What’s the lead time for bulk orders?Bulk orders usually take 15–30 days, but may vary during peak season or for special materials, depending on the order.

-

12. Do you have stock? Is the delivery on time?Some regular models are in stock. We strictly adhere to lead times.

-

13. Can I mix different models in one order?Yes, we support mixed batch shipments to meet the functional zoning requirements of floor paint in different regions.

-

14. What are your shipping methods?We ship by air, sea, or express. FOB and CIF terms are available.

-

15. Do you accept long-term partnerships or distribution agreements?Yes, we welcome long-term partnerships and offer special pricing and support.

-

16. Where is your factory located? Can we visit?Our factory is located in Nanxiong, Guangdong, China. Appointments for visits are welcome.

-

17. What payment methods do you accept?We accept T/T, L/C, global pay, etc.

-

18. Can you issue an invoice?Yes, we provide proforma and commercial invoices for customs and payment purposes.

-

19. Can you sign a Non-Disclosure Agreement (NDA)?Yes, we respect your IP and can sign an NDA before collaboration.

-

20. Do you provide a product manual or video?Yes, PDF manuals and operation videos are available for each product.

-

21. Can you provide product training?Yes, remote training is available to help clients quickly understand the product.

-

22. Do you provide after-sales service?Yes, we provide warranty support. If there's a quality issue, we offer returns or replacements.