Is it better to grind the cured floor with water or semi-dry grinding?

In floor paint installation systems, concrete polishing techniques directly determine final surface hardness, gloss levels, and longevity.

Wet grinding and semi-dry grinding emerge as two primary methodologies, requiring precise selection based on concrete properties,

environmental requirements, and project timelines.

I. Wet Grinding: Deep Penetration & Environmental Advantages

Wet grinding utilizes continuous water spray during polishing, delivering unique benefits. Its standout feature is superior environmental performance – water

cools grinding tools while completely suppressing dust, making it ideal for dust-sensitive floor paint applications in food plants and hospitals. Technically, water

lubrication increases cutting depth by 30%, particularly effective on old concrete with Mohs hardness above 7. Critically, this process opens capillary pores,

allowing penetrating hardeners to reach 8-10mm depth – far exceeding semi-dry grinding’s 3-5mm penetration.

However, wet grinding faces technical constraints. Wastewater treatment requires three-stage sedimentation tanks, increasing costs by approximately $2.5/m².

Post-grinding demands 72-hour dehumidification periods, especially in environments exceeding 80% humidity. Additionally, gloss levels typically cap at 55 GU,

delivering only matte finishes.

II. Semi-Dry Grinding: Balancing Efficiency & Gloss

Semi-dry grinding connects directly to industrial vacuum systems, offering notable efficiency gains. Daily coverage reaches 2,000m², significantly outperforming

wet grinding’s 800m². Aesthetically, it enables progressive polishing from 50 to 3,000 grits, achieving 80+ GU gloss that rivals epoxy floor paint mirror effects.

Real-time quality control allows immediate identification and repair of scratches or missed areas.

This method carries technical risks. Dust control requires 99.97% efficient vacuum systems costing over $20,000. On weak substrates, "edge chewing" may

occur

where grinding tools dislodge aggregates. Hard concrete scenarios increase tool wear by 40% compared to wet grinding.

III. Decision Guide: Four Critical Scenarios

Choose Wet Grinding When:

Environmental regulations dominate (pharmaceutical GMP facilities, schools, nursing homes)

Substrates exceed C50 concrete hardness or require metal aggregate floor renovations

Chemical warehouses demand maximum hardener penetration

floor paint projects prioritize depth over speed

Select Semi-Dry Grinding For:

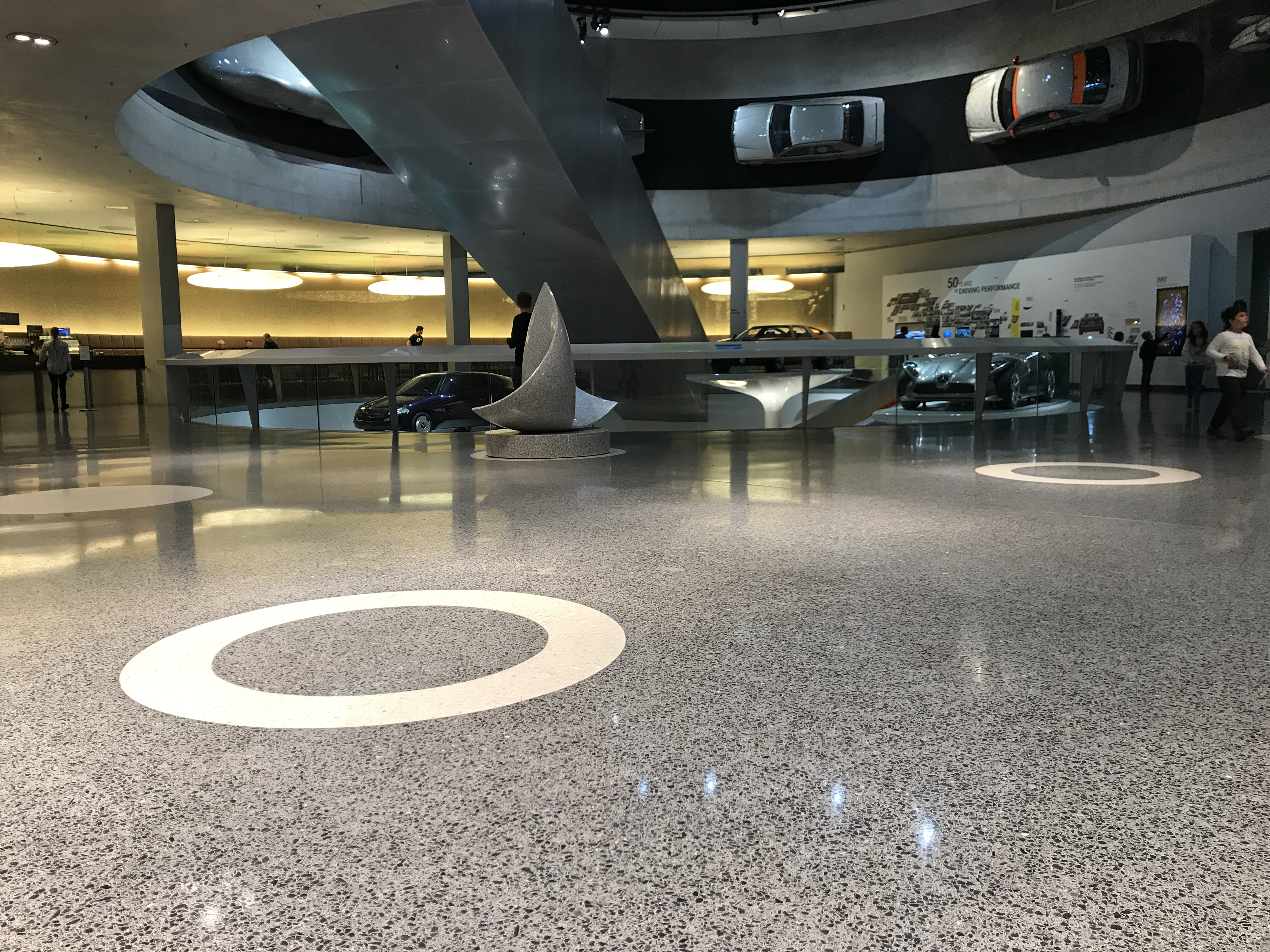

Commercial spaces seeking high-gloss finishes (shopping malls, showrooms)

Soft substrates under 20MPa compressive strength

Urgent projects requiring completion within 72 hours

Situations where floor paint aesthetics outweigh dust concerns

Hybrid approaches offer compromise: wet grind from 30-100 grits for dust control, then switch to dry grinding above 200 grits for enhanced gloss.

While increasing costs by 15%, this balances environmental needs with efficiency.

IV. Cost Analysis Insights

Pure Wet Grinding: $12-17/m², 4-5 days/1000m², 15+ year lifespan

Pure Dry Grinding: $9-13/m², 2-3 days/1000m², 10-12 year lifespan

Hybrid Approach: $14-18/m², 3-4 days/1000m², 18+ year lifespan

(Data sourced from 2023 Global Flooring Association Whitepaper)

Scientific polishing selection enhances hardened floor performance by 50%, preventing costly rework. Always conduct 3×3m test sections before full-scale

floor paint installation.

Link to this article:https://sprcoating.com/news/Which-cured-floor-is-better_112.html